Brick walls, renowned for their durability and timeless aesthetic, can sometimes develop cracks that compromise their structural integrity and appearance. These cracks, if left unattended, can worsen over time, leading to potential safety hazards and escalating repair costs. In such cases, Crack Stitching using Helical Bar emerges as a superior solution, offering distinct advantages over traditional cementitious repairs. In this comprehensive guide, we delve into the different types of cracks that can afflict brick walls, explore the benefits of Crack Stitching, and highlight its unmatched effectiveness in ensuring long-lasting, cost-efficient repairs.

Types of Cracks in Brick Walls:

- Vertical Cracks: These cracks commonly appear due to foundation settling or temperature fluctuations. They run vertically along the brickwork, indicating a need for immediate attention to prevent further damage.

- Horizontal Cracks: Often a sign of excessive pressure or structural movement, horizontal cracks can signify serious issues that require prompt intervention to maintain wall stability.

- Stair-Step Cracks: These diagonal cracks resemble a staircase pattern and can be attributed to shifting foundations or poor construction practices. Early detection and appropriate measures are crucial to prevent escalating problems.

The Power of Crack Stitching Using Helical Bar:

Crack Stitching using Helical Bar offers a permanent approach to repairing brick wall cracks. Its concealed strengthening capabilities make it a cost-effective choice for various crack types:

- Vertical Cracks: Helical Bar ties vertical cracks, effectively strengthening the brickwork and restoring structural integrity.

- Horizontal Cracks: Helical Bar’s tensile strength makes it perfect for reinforcing horizontal cracks, distributing stress evenly and preventing further widening.

- Stair-Step Cracks: Helical Bar restricts dynamic movement of stair-step cracks, halting their progression and sealing out moisture.

Durability and Cost-Effectiveness:

Compared to traditional repairs, Crack Stitching offers distinct advantages:

- Durability: Crack Stitching using Helical Bar ties brickwork using high strength Helical Bar ensuring that repaired areas retain their an increased strength, withstand structural stress, and resist future cracking, providing long-lasting results.

- Cost-Effectiveness: Crack Stitching using Helical Bar provides high strength, concealed repair and durability making it a cost-effective solution.

Advantages of Crack Stitching:

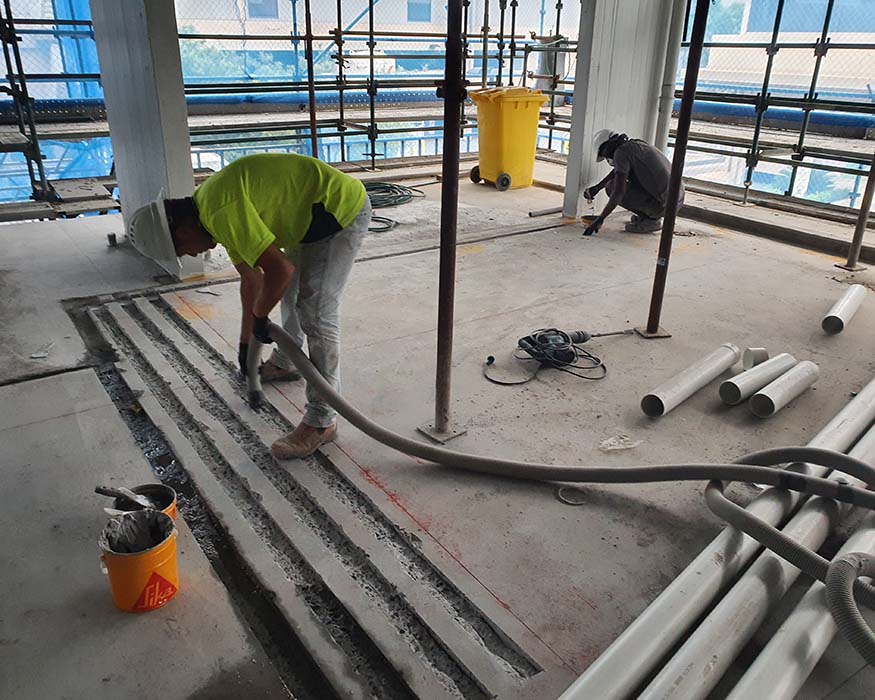

Crack stitching bars provide a permanent solution for masonry repairs and cracked wall reinforcement to suit vertical, stepped or corner cracks in masonry. When tying cracks in face brickwork these high strength bars are grouted into slots cut into mortar beds, ensuring the reinforcement is discreetly concealed once the mortar joint is pointed. Tensile forces are redistributed along the wall to dissipate load and minimise the risk of further cracking.

Cracks are repaired with no further damage to the wall, no costly or lengthy re-construction work and without inconvenience to the building’s occupants. The repair restores the structural integrity of masonry and provides resilience against further cracking of brickwork, while cementitious repairs can be visually noticeable.

FCS Concrete Repairs are experienced in the use of Helical Bar for Crack Stitching.

FCS Concrete Repairs can investigate and provide a competitive Quotation.

FCS Concrete Repairs recommends the use of Helical Bar supplied by ThorHelical Australia.

When to Worry about Cracks in Major Construction Sites:

Building structures that extensively comprise brickwork demand vigilant monitoring of cracks. If these cracks compromise the structural integrity, safety, or aesthetic appeal of the building, immediate action is paramount. Crack Stitching repair is particularly advantageous as its rapid application, concealed nature and minimal disruption allow for timely repairs without halting access.

In conclusion, Crack Stitching is an effective solution for repairing different types of cracks in brick walls. Its strength, durability, and cost-effectiveness surpass other traditional repairs. When confronted with cracks in building structures, the use of Crack Stitching techniques ensures efficient, enduring, and visually appealing solutions. Don’t let brick wall cracks undermine your structure—embrace the power of Crack Stitching for long-lasting, reliable repairs that stand the test of time.