Projects Successfully Completed by FCS Concrete Repairs

Client: Blue Mountains City Council

Location: Blue Mountains

Project: Leura Western Culvert

FCS Concrete Repairs has repaired this ageing culvert for our client, the Blue Mountains City Council, and helped to prolong its life.

Safety and Environmental Issues

Environmental Safety Precautions to protect this pristine environment were our first priority.

Employee Safety was also very important especially with visitors like this in the area.

Figure 1 Just Visiting: Brown Snake

Royal Flying Doctor Service – Snake Bite Safety

https://www.flyingdoctor.org.au/nswact/news/snake-safety-how-avoid-and-treat-bites/

This information could save your life.

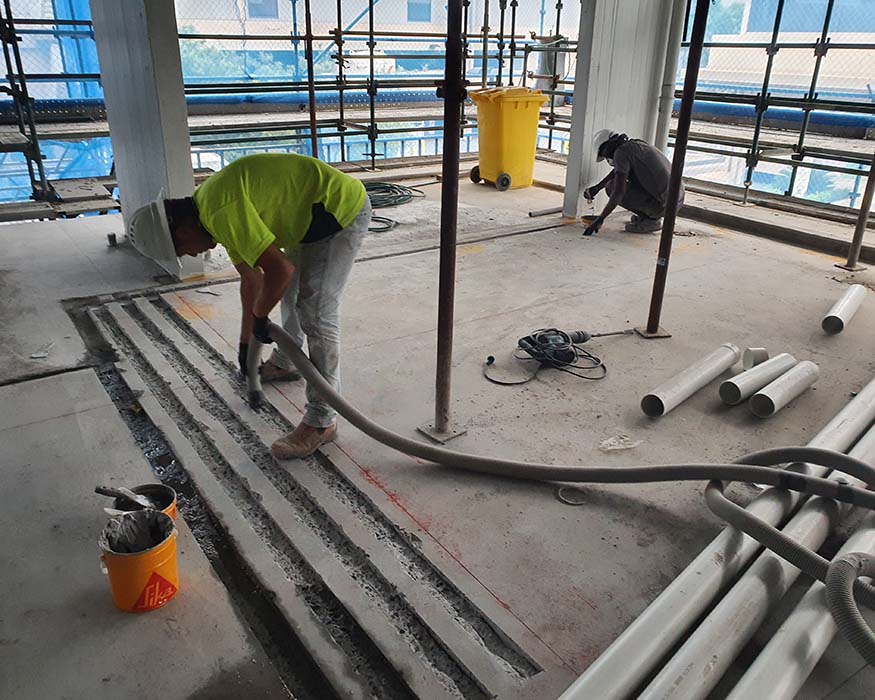

Nature of Work:

Concrete spalling repairs to internal surface of western culvert by breaking out exposed reinforcement and repair using ready to use mortars.

Repair Methodology:

- Prepare and submit an Environmental Management Plan (EMP) for the works.

- Install encapsulating bund platform.

- Breakout concrete to expose corroded reinforcement into sound concrete.

- Do not use abrasive blasting method.

- Minimum gap and cover 20-25mm.

- Breakout until non-corroded steel is reached plus 50mm.

- Clean exposed reinforcement to remove all corroded steel and foreign matter.

- Wash with low pressure water jet.

- Coat exposed steel with Sika® EpoCem®.

- Apply bond coat, Sika MonoTop 910 emulsion.

- Use Sika MonoTop repair mortar.

- Seal the entire internal surface of the culvert with corrosion inhibitor, plus hydrophobic impregnating coats:

- Apply Migrating Corrosion Inhibitor Application Sika® FerroGard®-903 Plus.

- Apply Sikagard®-706 Thixo is a Silane based water repellent impregnation cream.

- Wet Vac

- Pressure Clean on completion.

Products Recommended for this Project by FCS Concrete Repairs:

Sika® SikaTop 110 EpoCem®.

SikaTop® Armatec®-110 EpoCem® is a cementitious epoxy resin compensated 3-component coating material with corrosion inhibitor, used as bonding primer and reinforcement corrosion protection.

USE

- Suitable for control of anodic areas (Principle 11, method 11.1 EN 1504-9)

- Suitable in concrete repair as corrosion protection for reinforcement.

- Suitable as a bonding primer on concrete and mortar

- Suitable for Increasing cover in Low Cover Concrete rectification.

CHARACTERISTICS AND ADVANTAGES

- Contains EpoCem® technology – improved bonding agent

- Extended open times for repair mortars

- Compatible with most Sika MonoTop® repair mortars

- Excellent adhesion to concrete and steel

- Contains corrosion inhibitor

- Certified for application under dynamic load conditions

- Good resistance to water and chloride penetration

- High shear strength

- Long pot life

- Easy to mix

- Can be brushed on or applied using spray gun

- 2mm cured material equivalent to approx. 50mm of Concrete

Sika MonoTop 910 N

Sika® MonoTop®-910 N is a cementitious, polymer modified one-component coating material containing silica fume. (Replaces Monotop 610)

USE

Sika® MonoTop®-910 N is used as bonding primer and reinforcement corrosion protection for reinforcement and is suitable:

– For the control of anodic areas (Principle 11, method 11.1 of EN 1504-9)

– As a bonding primer on concrete and mortar

– In concrete repair as reinforcement corrosion protection

CHARACTERISTICS AND ADVANTAGES

– Easy to mix, just add water

– User-friendly application

– Excellent adhesion to concrete and steel

– Good resistance to water and chloride penetration

– Good mechanical strengths

– Can be brushed on or applied using spray gun

Sika MonoTop 352 NFG Repair Mortar

R3 light-weight, structural repair mortar. High build repair mortar, 4 – 75mm in one application. Excellent workability and finish and suitable for overhead and vertical applications. Low shrinkage

USE

- Suitable for restoration work (Principle 3, method 3.1 & 3.3 of EN 1504-9). Repair of spalling and damaged concrete in buildings, bridges, infrastructure and superstructure works.

- Suitable for repair works to concrete with a compressive strength of 25-45 MPa.

- Suitable for structural strengthening (principle 4, method 4.4 of EN 1504-9). Increasing the bearing capacity of the concrete structure by adding mortar.

- Suitable for preserving or restoring passivity (principle 7, method 7.1 and 7.2 of EN 1504-9). Increasing cover with additional mortar and replacing contaminated or carbonated concrete.

CHARACTERISTICS AND ADVANTAGES

- Polymer modified for increased durability

- Superior workability and finishing

- Suitable for hand and machine application

- Can be applied up to 75 mm thick per application layer

- Portable water approved to AS/NZS 4020:2005 – Testing of products for use in contact with drinking water

- Class R3 of EN 1504-3

- Low density but still suitable for structural repair

- Very low shrinkage behaviour

- Does not require a bonding primer even when manually applied

- Contains corrosion inhibitor Low chloride permeability

Sika® FerroGard®-903 Plus

Sika® FerroGard®-903+ is a unique blend of non-toxic, organic corrosion inhibitor based on amino alcohol and salts of amino alcohol technology, designed for use as an impregnation on hardened reinforced concrete.

Sika® FerroGard®-903+ penetrates the concrete and forms an adsorbed protective film on the surface of the steel reinforcement. The protective adsorbed film of Sika® FerroGard®-903+ reduces the rate of corrosion in carbonated and chloride contaminated concrete.

Reinforced Corrosion Controls of Culverts

Structure/Condition:

Reinforced concrete structure.

Chloride induced corrosion to internal and external deck surfaces.

Localised concrete damage.

Low concrete cover to reinforcement.

Requirements:

Reduce active corrosion rates and maintain passive corrosion levels.

Control corrosion by anodic and cathodic principles.

Provide up to 10 years additional protection before next maintenance.

Sika Solution:

Testing to prove penetration of Sika® FerroGard®-903 Plus to depth of reinforcement.

Clean concrete surfaces.

Concrete repairs using Sika® MonoTop® – 352 NFG

Application of Sika® FerroGard®- 903 Plus

Application of e.g. Sikagard® 706 Hydrophobic Impregnation.

Sikagard®-706 Thixo

Silane based water repellent impregnation cream. Ready for use

Long term efficiency, deep penetration. Low VOC content

USE

Sikagard®-706 Thixo is used as water-repellent impregnation (hydrophobic treatment) for absorbent substrates such as concrete in civil engineering or building concrete structures subjected to heavy stress due to freeze and thaw cycles and de-icing salts, chloride attack in marine environment, etc…

- Suitable for protection against ingress (Principle 1, method 1.1 of EN 1504-9)

- Suitable for moisture control (Principle 2, method 2.1 of EN 1504-9)

- Suitable for increasing the resistivity (Principle 8, method 8.1 of EN 1504-9)

CHARACTERISTICS AND ADVANTAGES

- Non-sag (thixotropic) consistency, allowing wastage-free application of sufficient quantities and assuring deep penetration

- Reduction of water absorption

- Reduction of absorption of aggressive or deleterious agents dissolved in water (i.e. de-icing salts or chloride from marine environment)

- No noticeable change of water vapour permeability

- Not film forming

- Ready for use

- Long term efficiency, deep penetration

- Increases the resistance of concrete to freeze and thaw cycles and de-icing salts

- Resistant to sea water

- Low VOC content