FCS Concrete Repairs have been engaged by the Gosford Council to rehabilitate two large manholes in the Gosford area.

FCS Concrete Repairs is experienced and fully resourced to carryout rehabilitation works for Water and Sewerage Infrastructure in confined spaces.

The Scope of Works for this project includes:

- Work health and safety management plan

- Safe work method statements prepared

- Inspection test plan prepared

- Task risk assessments prepared

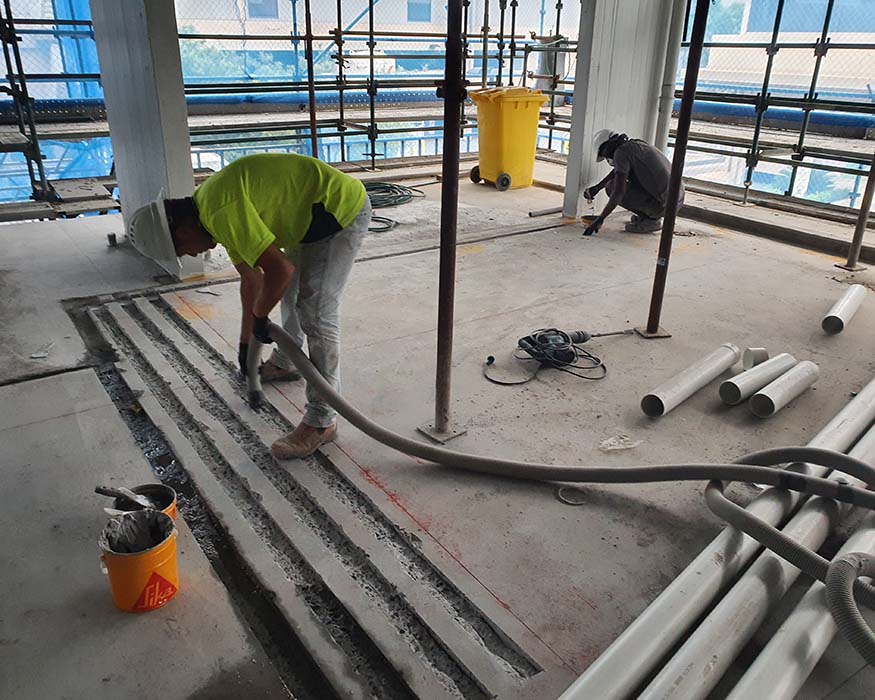

- Surface cleaning and removal of deteriorated concrete

- Wet blasting of exposed steel reinforcement

- Replacement of steel reinforcement, if required

- Protective coating of steel reinforcement

- Surface restoration including reinforcement splicing and coating

- Concrete remediation

- Tensile or bond strength testing

- Reinstatement of gatic covers and access ladders

The project works are carried out in confined spaces within the Drop Manholes over-night and strict safety precautions are required including the closure of the sewer mains.

The Problem: Biogenic Corrosion

When the right conditions exist in a sewer system, Acidophilic* bacteria feed on sulfur from H2S gas and release sulfuric acid that corrodes concrete, mortar, steel, and ductile iron. In the most severe cases, bacterial activity can destroy up to 25 mm of concrete per year.

The Solution: SewperCoat® Wet Spray

SewperCoat®’s outstanding durability in the most severe sewer environments relies on the unique “bacterio-static effect” of calcium aluminates. The metabolism of acid-generating bacteria is inhibited on calcium aluminate surfaces, thus maintaining a pH level above 3.

Description

SewperCoat® Wet Spray is a mortar designed to provide exceptional resistance to the biogenic corrosion environment found in sanitary sewers. The unique biogenic corrosion resistance of SewperCoat® Wet Spray is due to its 100% calcium aluminate composition, i.e. the combination of calcium aluminate cement and calcium aluminate aggregates.

SewperCoat® Wet Spray can be utilized to rehabilitate sewer infrastructures that have been damaged over years by biogenic corrosion. SewperCoat® Wet Spray can also be utilized to provide a protection lining to new infrastructures that will be exposed to biogenic corrosion conditions.

SewperCoat® Wet Spray is a cementitious mortar, fully compatible with the moist environment found in sewers.

Advantages

The unique properties of SewperCoat® Wet Spray result from the chemical and mineral phases formed during the hydration process. SewperCoat® is unique when compared to other materials such as ordinary portland cement (OPC) concrete, epoxies, poly-vinyl chloride (PVC) or polyethelene because of its ability to inhibit bacterial activity which drastically reduces the production of sulphuric acid. Key advantages of the SewperCoat® Wet Spray are as follows:

- Inhibits bacterial activity

- Neutralizes sulfuric acid

- Readily adheres to damp concrete

- Easy Monolithic installation

- Provides Long Term corrosion protection

- Contains no VOC’s

Preparation

Clean the surface and remove any dust, unsound or contaminated material, plaster, oil, paint, grease, corrosion deposits or algae. Where breaking out is not required, roughen the surface and remove any laitance by light scabbling or grit-blasting. The substrate should be thoroughly saturated with clean water prior to the spray application of the SewperCoat® Wet Spray. Under no circumstances shall the material be applied in an area where running water exists.

Application

In the wet spray process, the mortar is batched and mixed prior to being pumped along suitable hoses to the discharge nozzle. High velocity air is introduced at the nozzle to disperse the mortar and propel it into position. The impact of the mortar ensures excellent contact with the substrate and good compaction. As the material is batch mixed prior to pumping, the water content can be accurately controlled, ensuring a consistent product is applied to the substrate.

The spraying technique employed for each job will depend on the nature of the work and the materials used. Wherever possible, it is recommended that trials are performed with the material and equipment on elements which exhibit the same features as the job to ensure the spraying technique employed is appropriate. If sagging occurs during application to vertical surfaces, the SewperCoat® Wet Spray should be completely removed and reapplied at a reduced thickness on to the substrate.

Note: minimum applied thickness of SewperCoat® Wet Spray is 25mm. Equipment used must be clean and free of Portland cement build up to avoid accelerated set. Water addition to be between 2.7-3.00L per 20kg bag of SewperCoat® Wet Spray. Please refer to the SewperCoat® Wet Spray application guide for further information.

Properties

- Compressive Strength (MPa) (AS 1478.2 – 2005)

- 6 hours >20MPa

- 24 hours >40MPa

- 28 days >70MPa

- Modulus of Rupture (Flexural Strength) (MPa) (AS 1012.11 – 2000):

- 24 hours >4.5MPa

- 28 days >8.5MPa

- Indirect Tensile strength (AS 1012.10 – 2000): 28 days >3.5MPa

- Dimensional Change (Drying shrinkage) (AS 1478.2 – 2005): 56 days <600 microstrains

See Alternative CAC Product Brochure Here

Watch Sewpercoat in Action Here

FCS Concrete Repairs are experts in the repair and rehabilitation of Drop Manholes, Digester Systems, Screen Tanks and other Sewage Infrastructure works. FCS Concrete Repairs are on call to provide advice or carryout Specified Rehabilitation Works safely in a professional and cooperative manner.