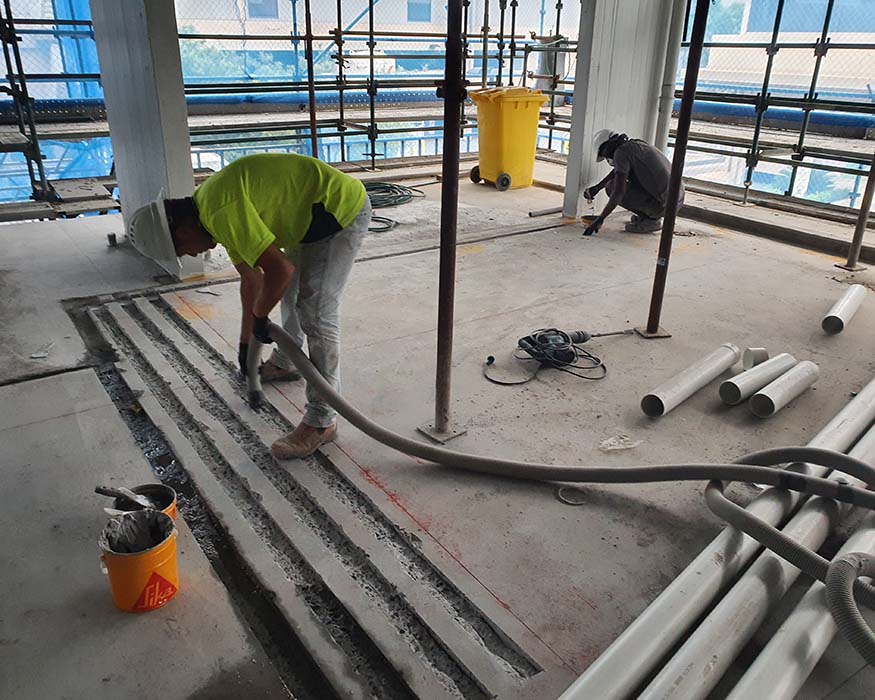

Description: A flexible 2-part polyurethane based elastomeric concrete mixed with part 3 proprietary aggregates with excellent bond to steel & concrete, high load bearing capacity, impact, vibration, chemical, oil resistant. Trafficable within one hour of application.

Principle Uses: Suitable for repairs to ways, highways, bridges, expansion joints and for installation of new expansion joints.

Coverage/Yield: 1800 kg/m3

Condur ARP Advantages

- Flexible & do not need to destroy the surrounding concrete

- Epoxy & most other high early strength repair materials prematurely fail because they are rigid.

- Rigid repair materials installed in rigid pavement require that both the materials have similar coefficient of expansion. Most do not and as a result destroy the surrounding patch & concrete.

- Condur ARP provides a flexible patch that will deflect as surrounding concrete expands and contracts rather than destroy it.

- High compressive stress & elasticity unlike epoxies, Condur ARP can handle heavy pressure before deflecting and allows itself to return to its original state after deflection.

- High impact resistant – under bitterly cold conditions Condur ARP withstands heavy impact unlike epoxy and concrete-based materials that shatter.

- Resistant to chemicals & discolouration over time – excellent U.V. resistance.

- Excellent adhesion to steel and concrete.

- Greater compressive strength along with better impact resistance.

- Can be easily installed with early strength gain & flexibility.

- Can accept traffic in approx. one hour.

- Fully cured material is resistant to changes in temperature.

- Use as a pourable sealant in expansion joints.

- Withstands heavy loading.

- Resistant to chemicals & fuel oils.

PROPERTIES

Final Setting Time @25oC: Approx. 60 min.

Specific Gravity @25oC: Approx. 1.8 kg/litre

Rheological Properties

(Immediately after mixing): Self-Leveling.

Tensile Strength: > 5 MPa. ASTM D638

Elongation at Break: > 50 % ASTM D638

Shore D Hardness: Approx.55-60 (Full Cure) ASTM D2240

Impact Resistance: No crack or breaks observed. ASTM D3029

Abrasion Test: 139 Mg/1000 cycles

Compressive Strength: 7 Days @25oC 7.5 – 12 N/mm2 ASTM C579

Trafficable at 25oC: Approx. 1 hour.

Full Cure Time at 25oC: 7 Days

Adhesion Bond Strength: 3.2 N/mm2 to Concrete @ 7 Days ASTM D4541

Chemical Resistance: Dilute sulphuric acid

Dilute NaOH solution

Sea water

Chlorine water

Waste water

Glycerine

Soap solution

Fuels & oils ASTM D543