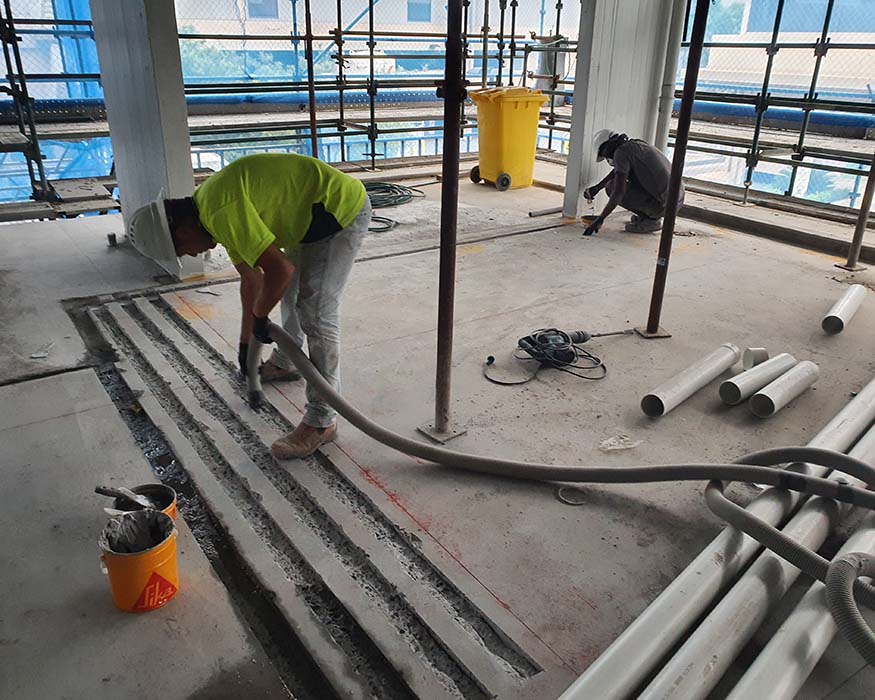

FCS Concrete Repairs are experts in the repair of damaged factory and warehouse floors.

FCS Concrete Repairs have the experience in all facets of concrete repair:

- Concrete Floor Repair and Crack Injection

- Concrete Wall Repair and Crack Injection

- Joint Filling

- Reinforced Concrete Replacement

- Concrete Patch Repairs

- Flexible Concrete Infills Across Joint [Latest Technology – Elastomeric Concrete]

- Delaminated Concrete Topping Repair

- Grated Drain Repair

Does this look like your factory or warehouse floor or your external paving?

Typically, concrete floors in factories and warehouses require repair due to:

- Forklift damage

- Cracking

- Joint failure

- Surface delamination, scaling, dusting

- Sub-base subsidence, wash-outs, voids

- Chemical damage

- Design issues

- Wear and tear

If your factory or warehouse floors are affected by any of these issues then FCS Concrete Repairs have the experience and expertise to investigate, test, diagnose and recommend the most cost effective course of action to repair the floor and mitigate any further deterioration or future damage.

Concrete floors suffer this damage due to a large number of contributing causes:

- Forklift damage to floor joints and floor areas

- Heavy Loading damage to floors

- Failure when design limits are exceeded

- Subsidence of the sub-base

- Washout of the sub-base

- Poorly compacted sub-base

- Structural cracking

- Cold storage damage to floors

- Machinery loading on floors

- Machinery vibration impacts

- Concrete dusting

- Concrete wear and tear

- Rusting of internal reinforcement steel

- Potholes

- Floor demarcation line and safety marking wear

- Ingress of water

- Chemical damage

- Ground movement

- Stress loadings

- Temperature changes

- Product contamination of floor surface

- Delamination of concrete toppings

- Surface scaling

- Deterioration of applied coatings

- Plastic shrinkage cracking

- Overworking of surface during concrete placing

- Inadequate curing

- Premature surface sealing during concrete placing

- Improper concrete compaction

- Excessive moisture loss during concrete placing

- Poor structural design

It is important to determine the root cause of the concrete failure and develop a strategy to remedy the cause and complete an effective repair with a minimum of disruption to operations by delivering the best possible outcome.

FCS Concrete Repairs have a strong knowledge base to ensure that any repairs are effective. Our extensive prior experience in concrete construction, concrete repair techniques, selection of the appropriate repair methods and the right repair materials for the job will ensure a quality repair. There are a wide range of repair materials and selection of the correct material and methodology is critical to a successful outcome.

FCS Concrete Repairs repair techniques include:

Concrete Floor Repair and Crack Injection

Concrete Wall Repair and Crack Injection

Joint Filling

Reinforced Concrete Replacement

Concrete Patch Repair

Flexible Concrete Infills Across Joint [Latest Technology – Elastomeric Concrete]

Delaminated Concrete Topping Repair

Grated Drain Repair

FCS Concrete Repairs are members of ACRA, the Australasian Concrete Repair Association.

FCS Concrete Repairs are the Preferred and Approved Contractors to the major material suppliers such as Prime Resins in the USA, Parchem, Sika, Epirez, International, Fosroc, Dulux and Thorhelical Remedial Solutions.

FCS Concrete Repairs are quality accredited:

REPUTATION FOR QUALITY

Our reputation is important to us and is built upon experience and an understanding of the importance of the full and thorough preparation of the repair area. Inadequate preparation and short cuts are not the answer to an effective repair and a sound LONG TERM solution.

THE CHEAPEST PRICE IS NOT ALWAYS THE ANSWER but FCS Concrete Repairs can offer a competitive solution without sacrificing quality.

If your property is in need of repair please contact us, firstly, for an inspection, secondly, for advice and, thirdly, for our recommended solution and competitive quotation.