Problem: Sinkholes had developed around storm drainage manholes in grassy areas of a military housing subdivision in Richmond, Virginia.

Identifying the source: To pinpoint the sources of the problem, the contractor’s crew flooded the existing sinkholes and monitored the dry manhole to see where the infiltration entered.

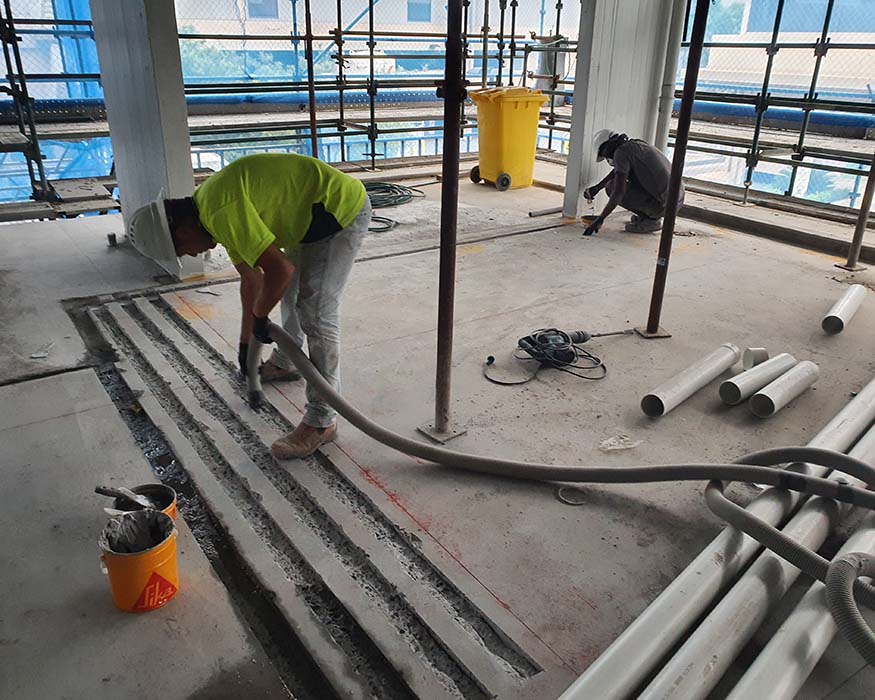

Solution: With on-site technical support from Prime Resins, the contractor injected Prime Flex 920 through the manhole wall to fill the voids and create a watertight curtain around the manhole. Prime Flex 920 is an expansive, hydrophobic polyurethane resin that reacts to form a rock-hard watertight mass. The grouting was done from inside the manhole because the repair locations were so deep, as much as 20 feet from the surface. Probe grouting from the surface outside the manhole can be done if the manhole is too narrow to work within.

They installed four injection ports per pipe and injected each leak location starting at the lowest point and working up. This revealed a leaking injection hole from the previous repair attempt. Some 920 seeped out this hole and sealed it as well. The technicians repaired wide gaps around the main connection plus spalls and chips inside the collar using the activated oakum technique. They soaked oil-free oakum with Prime Flex 900 XLV and pushed it into the gaps where the reacted resin sealed the openings. The 900 XLV is a very low viscosity polyurethane and is hydrophilic, so it creates a tenacious bond with the wet concrete.

Outcome: The crew tested their repair by flooding the sinkhole again. No water drained into the manhole: their repairs stopped the infiltration. Finally, they removed the ports and plugged the holes with hydraulic cement.

Read the complete case study here.

FCS Concrete Repairs are experts in leak repair and are available to help with your concrete repair requirements. FCS Concrete Repairs are approved applicators for Prime Resins in Australia.