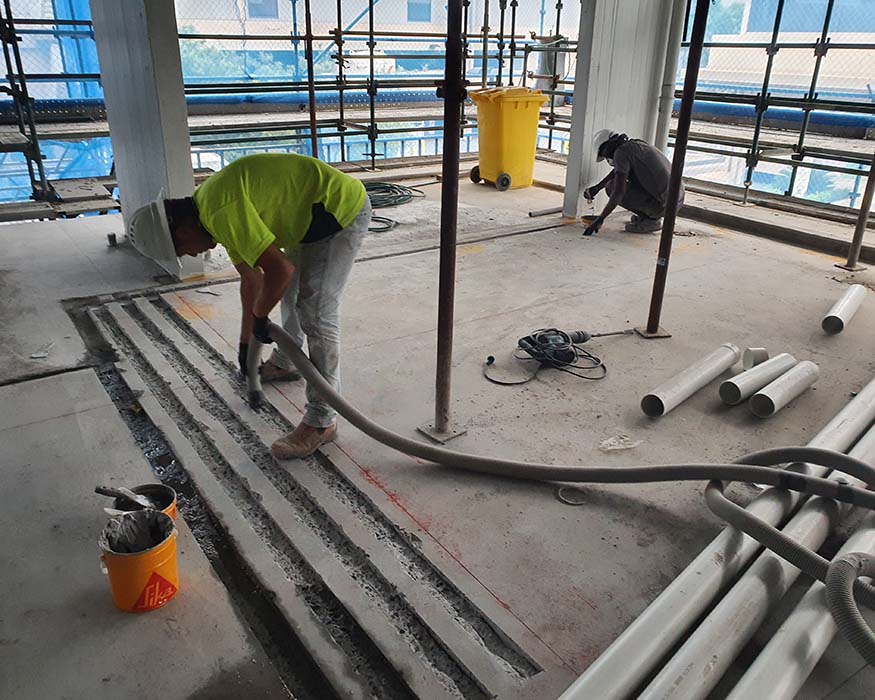

[vc_row][vc_column][vc_custom_heading text=”PROCESS: INSTALLATION OF CARBON FIBRE REINFORCED POLYMER STRENGTHENING (CFRP) TO REINFORCED CONCRETE SOFFIT” font_container=”tag:h2|text_align:left|color:rgba(10%2C10%2C10%2C0.66)” google_fonts=”font_family:Lato%3A100%2C100italic%2C300%2C300italic%2Cregular%2Citalic%2C700%2C700italic%2C900%2C900italic|font_style:400%20regular%3A400%3Anormal”][vc_separator][vc_column_text]FCS Concrete Repairs successfully tendered to carryout structural strengthening to the soffit of a strata unit at Manly.

Our client’s Engineer advised FCS Concrete Repairs that the unit’s soffit required strengthening and provided a marked up drawing indicating where the specified product, Sika Carbodur S1214 strengthening strips, were required to be installed.

The process of installation was carried out by FCS Concrete Repairs experienced trained staff in accordance with the manufacturer’s specifications and the client’s engineering design.[/vc_column_text][vc_column_text]Note: FCS Concrete Repairs staff have received instruction from Sika Australia training personnel and FCS Concrete Repairs is a Sika approved applicator.

The process was as follows:

- Prior to commencement the soffit substrate quality was established using the Pull-off tests with a minimum requirement of 1.5MPa and tested to ensure that moisture content was less than 4% pbw.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_gallery interval=”3″ images=”2684″ img_size=”medium”][/vc_column][vc_column width=”1/3″][vc_gallery interval=”3″ images=”2685″ img_size=”medium”][/vc_column][vc_column width=”1/3″][vc_gallery interval=”3″ images=”2686″ img_size=”medium”][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

- The surface to be strengthened was levelled where necessary to provide maximum

.

. - The substrata was cleaned of any contaminants and loose material.

- The substrata was tested to ensure that moisture content was less than 4% pbw.

- Ambient temperature was between the required 8°C and 35°C.

- Substrate temperature was atleast 3°C above the dew point.

- Sikadur 30 adhesive was used to fix the Sika CarboDur S1214 Carbon Fibre Reinforced Polymer strips(CFRP) to the soffit and was mixed as per the Sika product Technical Data Sheet.

- Sikadur–30 is a thixotropic adhesive mortar based on a 2-component solvent free epoxy resin which has the following properties required for the application of the product to the soffit:

[/vc_column_text][vc_column_text]Tensile Properties (ASTM D-638)

Tensile strength is a measurement of the force required to pull something such as rope, wire, or a structural beam to the point where it breaks.

7 day Tensile Strength 3,600 psi (24.8 MPa)

Flexural Properties (ASTM D-790)

Flexural strength, also known as modulus of rupture, or bend strength, or transverse rupture strength is a material property, defined as the stress in a material just before it yields in a flexure test.

14 day Flexural Strength (Modulus of Rupture) 6,800 psi (46.8 MPa)

Shear Strength (ASTM D-732)

Shear strength represents how hard you can try to cut it without it breaking.

14 dayShear Strength 3,600 psi (24.8 MPa)

- Sika CarboDur S1214 CFRP strips were installed in the designated locations on the soffit of the unit using the Sikadur 30 adhesive.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

Sika CarboDur can be used to strengthen reinforced concrete due to loading increases, structural damage, changes in the structure or design or construction defects.

Sika CarboDur can be used to strengthen reinforced concrete due to loading increases, structural damage, changes in the structure or design or construction defects.- Sika CarboDur S1214 is 120mm wide, 1.4mm thick and can achieve very high tensile and flexural strengths:

Elastic Modulus >165,000 MPa

Tensile Strength >2,800 MPa

Mean Value of Tensile Strength at Break > 3,050 MPa

- Sikadur 30 was first applied to the soffit to a nominal thickness of 1.5mm and then to the Sika CarboDur laminate also to a thickness of 1.5mm.

- The laminate was then placed on the surface of the soffit and rolled into the epoxy resin adhesive.

- Sikadur 30 reaches it’s design strength after 7 days.

RESULT: The end result was that the soffit of the unit was structurally strengthened to the specifications of the client’s Engineer cost effectively without the need for any costly structural concrete modifications.[/vc_column_text][/vc_column][/vc_row]